Introduction to CNC Machining Efficiency

Efficiency is a key factor in CNC machining, where reducing idle time and maximizing machining time directly impact profitability. One of the most effective ways to enhance CNC productivity is by clamping multiple workpieces on the machine table at once. Whether using identical or different workpieces, multiple part clamping significantly improves operational efficiency, reduces machine stoppages for setup changes, lowers the tool change frequency, and enables extended unattended machining.

In this article, we will explore the benefits, challenges, and solutions associated with multi-part clamping.

Understanding CNC Machining Idle Time and Productivity

What is Idle Time in CNC Machining?

Idle time in CNC machining refers to the periods when the machine is not actively cutting or shaping a workpiece. This can occur due to:

- Workpiece changes (setting up)

- Tool changes during the machining cycles

- Machine setup adjustments

- Operator interventions

- Processing errors

How Does Idle Time Impact Productivity and Costs?

Idle time leads to:

Lower throughput – Fewer parts machined in a given time.

Higher costs – Higher machine hourly rate and higher costs per machined workpiece, due to larger machine down time (low machine productivity).

Reduced profitability – More downtime means lower machine utilization.

Multiple part clamping helps address these challenges by minimizing idle (downtime) time and maximizing productive machining cycles.

The Concept of Clamping Multiple Workpieces in CNC Milling

What is Multiple Part Clamping?

Multiple part clamping involves fixing multiple workpieces (same or different) onto a CNC machine table simultaneously. This method ensures that machining continues for a longer cycle without operator intervention. It also enables the operator to work on more than one machine simultaneously (E.g. two or three).

Why is it Beneficial for CNC Machining?

- Extends unattended machining time – Machines can run longer without manual intervention.

- Reduces setup frequency – Multiple workpieces are clamped once, eliminating repeated setups.

- Minimizes tool changes – The same tool performs operations on all workpieces before being returned to the tool magazine.

- Enhances workflow efficiency – Multiple part clamping optimizes CNC machining schedules and maximizes output.

Key Benefits of Clamping Multiple Workpieces in CNC Milling

1. Reduced Operator Intervention & Increased Unattended Run Time

By securing multiple workpieces at once, CNC machines can run for extended periods without requiring operator attention. This allows machinists to:

- Manage multiple machines simultaneously.

- Focus on higher-value tasks like programming and quality control.

2. Cost-Effective Machining with Fewer Set-Ups

Each time a workpiece is clamped, the operator spends valuable time setting it up. Multi-part clamping significantly reduces these setups, leading to:

- Lower cost per machined part

- Reduced machine downtime – more machine productivity

3. Reduced Tool Changes and Machining Productivity

When clamping series of same workpieces, instead of changing tools multiple times for individual workpiece, a single tool can perform the same operation across multiple workpieces before being swapped out. This results in:

- Saved time through fewer tool changes across the machining process

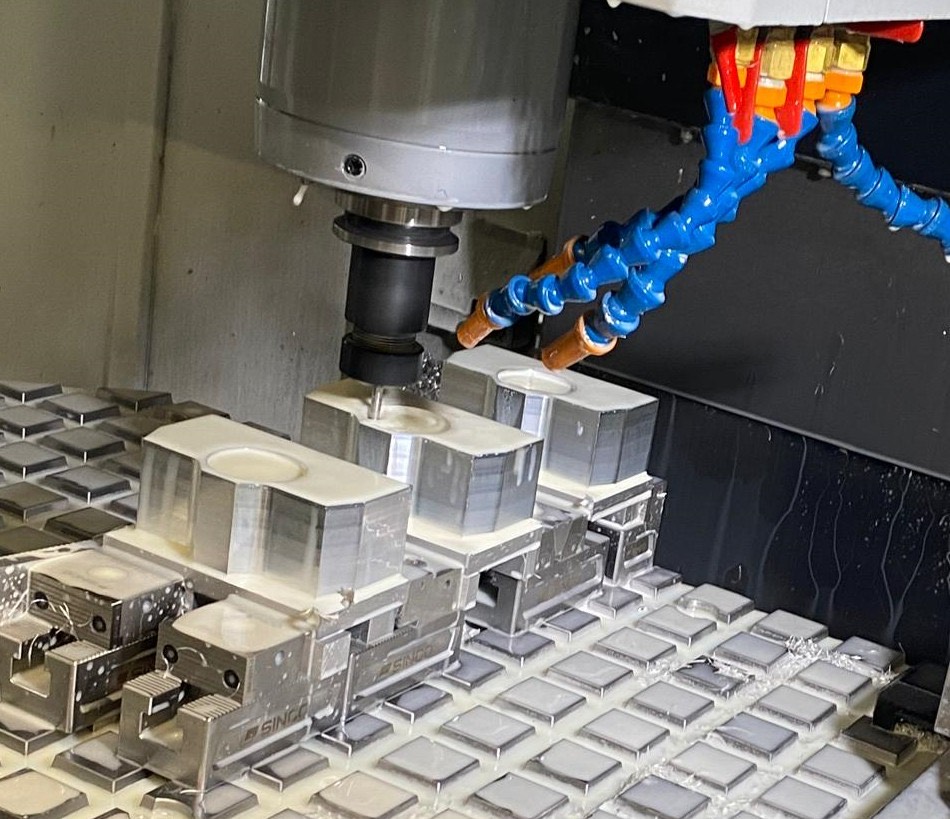

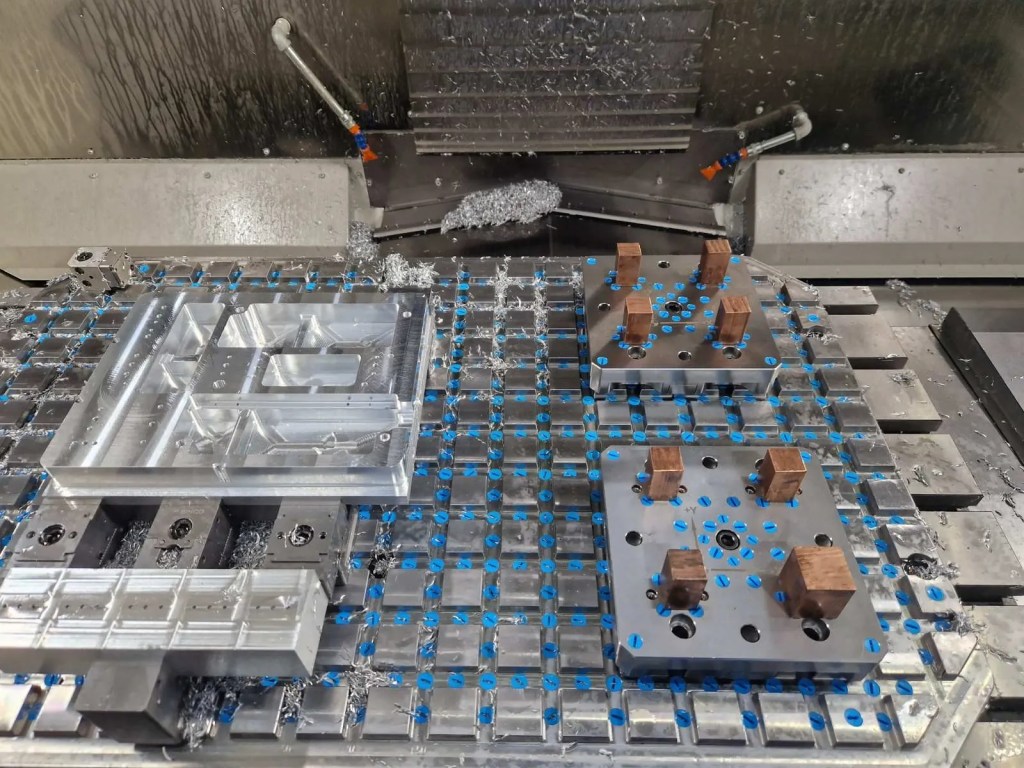

Different aluminium workpiece clamped with MultiZero Modular Vises on the MultiZero Base Plate, with additional copper workpieces prepared for electrode production on MultiZero EDM Pallets.[/caption]

Different aluminium workpiece clamped with MultiZero Modular Vises on the MultiZero Base Plate, with additional copper workpieces prepared for electrode production on MultiZero EDM Pallets.[/caption]Challenges of Machining Multiple Workpieces

Challenges in programming and clamping

- Complex CAM programming – Requires careful toolpath planning.

- Variation in workpiece sizes – Different geometries need adaptable workholding solutions.

- Fixturing considerations – Flexible workholding is necessary to accommodate different or generally larger number of parts.

Solutions for Multi-Part, Mixed Workpiece Clamping

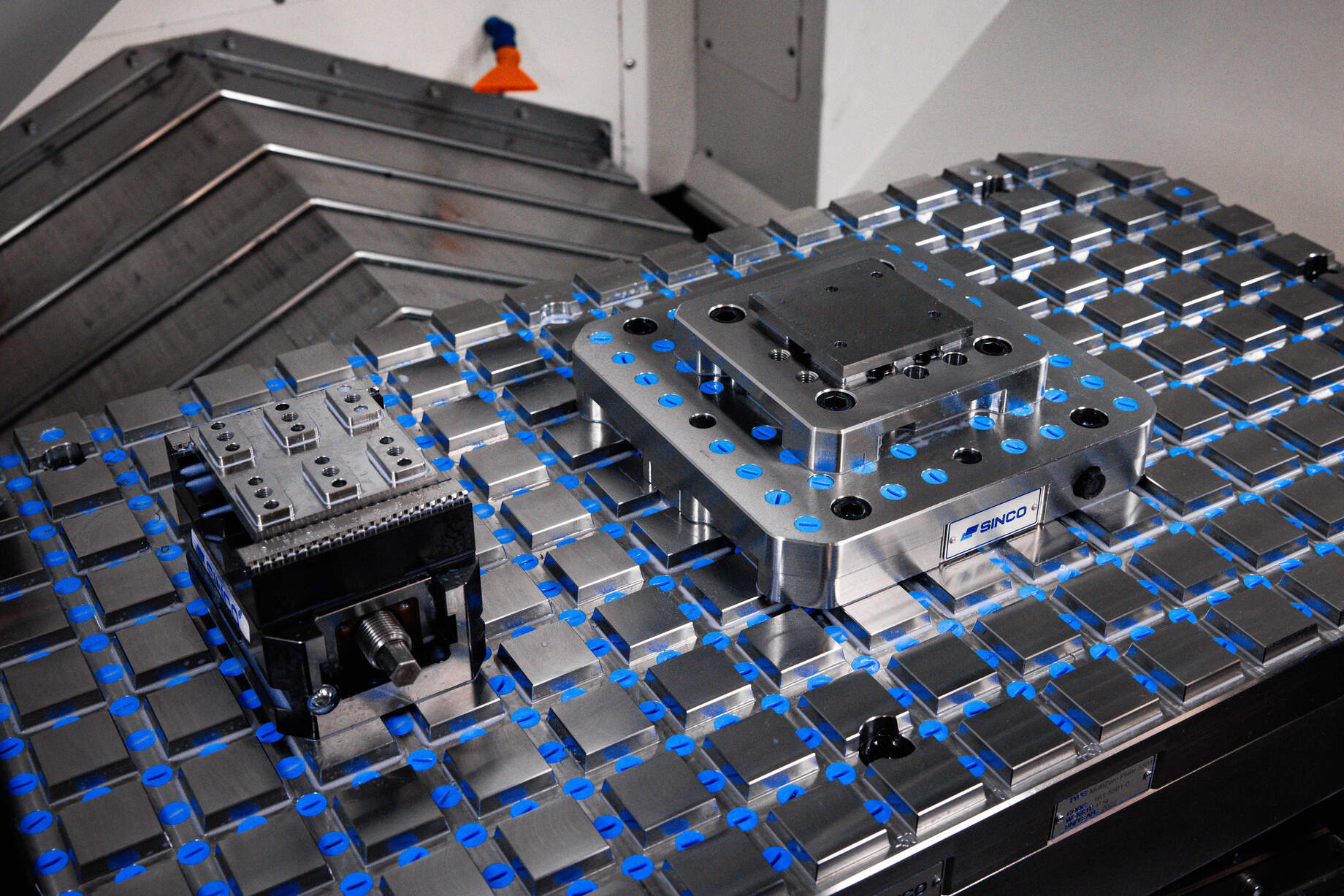

- Standardized & modular workholding – Using standardized and modular workholding that can adapt to different workpieces and workholding needs.

- Advanced CAD/CAM integration – Pre-planned clamping strategies improve programming efficiency.

- Zero-point clamping systems – These clamping systems enable quick and repeatable positioning of different workpieces.

Optimizing Workholding for Multi-Part CNC Machining with MultiZero Clamping System

The Role of efficient Clamping System in Multiple Part Clamping:

- Should enable adaptability & flexibility – Accommodates different part geometries and large number of workpiece without extensive modifications.

- Should enable faster workpiece changes – Reduces downtime.

- Should enable repeatable accuracy – Ensures consistency across multiple workpieces.

Flexible Zero-Point Clamping System as a major solution to Multiple workpiece machining

A rigid and precise, but more importantly adaptable workholding setup in very important when we want to efficiently apply multiple part clamping to our process. A flexible zero-point clamping system, like the MultiZero Clamping System by SINCO is the right tool for the job and provides:

- Zero-point positioning on pitch 50mm or 100mm (zero-point reference on each conical cross section) for large amount of options for workholding placement,

- Large number of standardized workholding equipment like modular vises, risers, clamping pallets, etc.,

- Support elements that work as support of workpiece during machining or as stoppers for automatic positioning of the workpieces,

- Base plates that can cover the whole machine table for maximum table coverage and clamping freedom,

- 3D models of each workholding element that can be applied to planning of clamping in CAD/CAM stage.

MultiZero Clamping System’s modular zero-point structure allows longer cycle times, freeing operators to focus on running multiple machines simultaneously, further enhancing productivity.

Want to learn more? Check out how MultiZero Clamping System can change your machining operations: https://sinco.eu/multizero-clamping-system/

Conclusion

In today’s competitive manufacturing landscape, maximizing CNC machine utilization is essential for increasing efficiency and reducing operational costs. Multiple workpiece clamping is a game-changing strategy that significantly enhances productivity by reducing idle time, minimizing tool changes, and extending unattended machining hours. Whether clamping identical or different workpieces, this approach leads to higher output, lower costs, and greater flexibility in machining operations.

Multiple workpiece clamping, when properly integrated into machining workflows, presents a transformative opportunity for improving machine shop efficiency and profitability. A well-structured approach, supported by precise and toughtful CAM programming and modular workholding system, allows for optimized machine utilization, reduced idle times, and higher output rates. Shops that adopt this strategy will not only streamline their processes but also gain a competitive edge in an increasingly demanding manufacturing landscape.